D2300 series micro differential pressure gauge

Special for hospital (especially suitable for quarantine wards), accurate measurement, measuring range + 30 ~ -30pa, using frictionless magnetic parts, anti-vibration, anti-shaking and high anti-overpressure capability to measure air or non-corrosive gases.

Product Overview

The D2300 series micro-differential pressure gauge is an elastic differential pressure instrument that utilizes advanced spiral magnetic coupling technology and employs a rubber diaphragm as the sensitive element. When a differential pressure (including positive and negative pressures) acts on the two pressure chambers isolated by the diaphragm, the diaphragm deforms, causing the central part to displace. This displacement drives the leaf spring equipped with a magnetic steel for range adjustment to move, which, through magnetic coupling, rotates the spiral shaft. Simultaneously, the pointer rotates along with the shaft, indicating the pressure difference value on the instrument's dial, thus achieving the purpose of measuring differential pressure.

Due to the use of frictionless magnetic components as the core components of the instrument, it exhibits resistance to vibration, shaking, and high overpressure, making it highly suitable for measuring micro-pressure and differential pressure of air or non-corrosive gases.

Product Usage

Blood pressure and respiratory pressure monitoring in healthcare equipment, positive pressure indication in clean rooms of the semiconductor and biomedical industries. Fields such as negative pressure isolation wards in hospitals, ICU intensive care units, operating rooms, biosafety cabinets, negative pressure ambulances, and differential pressure monitoring of central air conditioning unit filters. The product is easy to use, maintain, and install.

Product performance

The D2300 series pointer-type micro differential pressure gauge is an elastic pressure gauge that utilizes a simple, frictionless magnetic spiral movement and a rubber diaphragm as the sensitive element for measurement. It can quickly indicate the pressure of the measured gas using a pointer, whether it is positive pressure, negative pressure, or differential pressure. Moreover, there is no need to fill the gauge with liquid, thus eliminating issues such as gasification, freezing, and odor.

●The gas being tested must be non-corrosive to avoid corroding sensitive components such as rubber diaphragms.

●The gas being tested must not contain dust or other particles, to prevent blockage of the gas pores and adhesion to the internal components of the instrument.

● Choose a location with no vibration and an ambient temperature ranging from -7 to 60℃ for use. Avoid direct sunlight to prevent the plastic panel from aging.

Technical Specifications

● Medium: Air and non-flammable, compatible gases

● Measurement range: minimum -30~+30Pa, with multiple measurement ranges available

● Accuracy: ±4% F.S as the standard

● Pressure range: -20Hg to 15 psig (-0.677 bar to 1.034 bar)

● Housing: Cast aluminum or ABS housing, with a beveled panel made of plexiglass. Dark gray coating, capable of withstanding 168 hours of salt spray testing

● Temperature range: -6.67 to 60°C (20 to 140°F)

● Hole size: 114mm

● Installation direction: vertical installation

● Connectors: Identical 1/8" NPT high and low pressure connectors, with one pair on the side and one pair on the back

● Weight: 500g/piece

● Standard accessories: Two 1/8" NPT threaded connectors, used as high and low pressure connectors and connected to rubber hoses;

Two 1/8"NPT plugs for blocking the remaining two high and low pressure ports; three threaded flush-head mounting connectors.

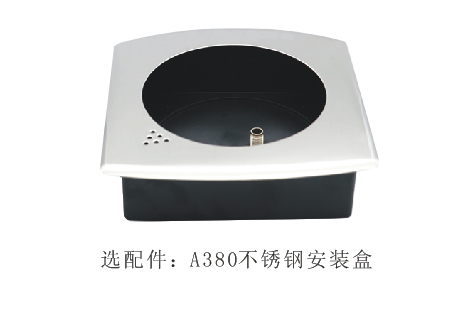

● Installation box: stainless steel installation box is optional

Ninth Floor, China Sound Valley Incubation Building, Intersection of Xiyou Road and Shilian South Road, Hefei High-tech Zone

Ninth Floor, China Sound Valley Incubation Building, Intersection of Xiyou Road and Shilian South Road, Hefei High-tech Zone Tel:400-161-8008

Tel:400-161-8008

Mail:duwei@duwei-inst.com

Mail:duwei@duwei-inst.com