DW901static pressure type liquid level transmit

DW901 series static pressure liquid level transmitter is a kind of measuring instrument adopting static pressure principle to measure liquid level, which is designed for liquid level measurement in reservoir, sewage treatment, water conservancy project, waterworks, underground water, well water, canal, lake, power plant and other general occasions in the industries of petroleum, chemical industry, electric power, paper making, food, medicine, etc.

Overview

The DW901 series static pressure liquid level transmitter is a measuring instrument that uses the principle of static pressure to measure liquid level. It consists of a high-precision and high stability IC diffusion silicon piezoresistive pressure sensor and a single-chip precision integrated transmitter circuit. The liquid level can be converted into a 4-20mA DC standard current signal, and the shell is made of 316L stainless steel sealed structure. Thus achieving measurement and control of liquid level.

The product is designed for liquid level measurement in industries such as petroleum, chemical, power, papermaking, food, and medicine, including reservoirs, sewage treatment, as well as water conservancy engineering, waterworks, groundwater, well water, canals, lakes, power plants, and other general occasions.

Characteristics

Using 316L stainless steel casing, IC SENSORS high-performance pressure sensor measures static water level. After temperature compensation, it has excellent linearity and repeatability. The liquid receiving part is entirely made of stainless steel structure, which has strong corrosion resistance, no movable parts, good sealing performance, and easy installation. It can be applied to highly corrosive or viscous liquids.

working principle

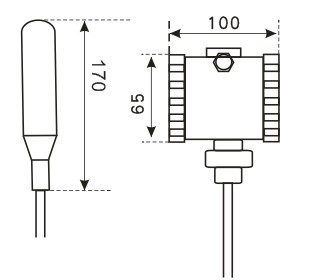

The DW901 series static pressure liquid level transmitter consists of three parts: measuring probe, junction box, and fixed connector. The liquid level height is measured by sinking the pressure sensor probe into the bottom of the container, and the hydrostatic pressure of the liquid is expressed by the formula P=Po+ρ gh. Among them, Po is the atmospheric pressure at the upper part of the liquid surface, ρ is the density of the measured liquid, H is the height of the liquid column, and g is the gravitational acceleration (constant). In order to eliminate the influence of atmospheric pressure on the upper part of the liquid surface, the DW901 transmitter adopts a design scheme of through-hole breathable cable, which introduces PO into the back of the sensor pressure sensing surface to offset the influence of Po. It can be seen that the pressure P detected by the sensor is linearly related to the measured liquid level. The pressure signal is converted into a 4-20mA DC output signal by a single-chip integrated V/I transmitter, and the height of the liquid level can be determined by measuring (recording) the output current value. When the output current reaches the set current value, a control or alarm signal can be issued through the optional controller.

The sensor probe must be suspended or fixedly installed at a certain height position to achieve accurate measurement. When the medium flows or is greatly disturbed, the probe should be installed on a support frame or with a heavy hammer and suspension chain, or the probe can be placed in a wave tube.

Technical Specifications

Applicable medium: Suitable for media coexisting with 316 stainless steel and polyethylene, and Hastelloy alloy can measure strong corrosive media

Measurement range: 0-0.5m to 0-600m

Accuracy: 0.2% F.S

Working temperature: -20 ℃~80 ℃ (medium without crystallization)

Storage temperature: -40 ℃ to 125 ℃

Temperature coefficient: zero point and ± 0.015% F.S/℃

Long term stability: ± 0.1% F.S/year

Range Migration: Models using silicon sensors have zero/range unavailability and output offset<2% F.S. Models using ceramic capacitive sensors have a migration ratio of 5:1

Power supply voltage: 12~36VDC standard 24VDC

Output signal: two-wire system 4-20mA

Load characteristics: Load resistance ≤ 600 Ω at standard 24VDC

Overload: 3 times full range

Current limiting protection: In case of overload, the power supply is limited to a nominal 26mA

Protection level: probe IP68, junction box IP67

Explosion proof grade: intrinsic safety explosion-proof grade ia Ⅱ CT5

Ventilation cable: Polyurethane gas conducting cable, combined with polymer sieve.

Ninth Floor, China Sound Valley Incubation Building, Intersection of Xiyou Road and Shilian South Road, Hefei High-tech Zone

Ninth Floor, China Sound Valley Incubation Building, Intersection of Xiyou Road and Shilian South Road, Hefei High-tech Zone Tel:400-161-8008

Tel:400-161-8008

Mail:duwei@duwei-inst.com

Mail:duwei@duwei-inst.com